synTQ: Transforming the industry with efficient, cost-effective solutions

Get in touch for a tailored business case analysis of the ROI possibilities derived from PAT powered by synTQ.

One of our experts will be in touch to book a slot for your free consultation.

Videos

Introduction to synTQ

The PAT Implementation Approach

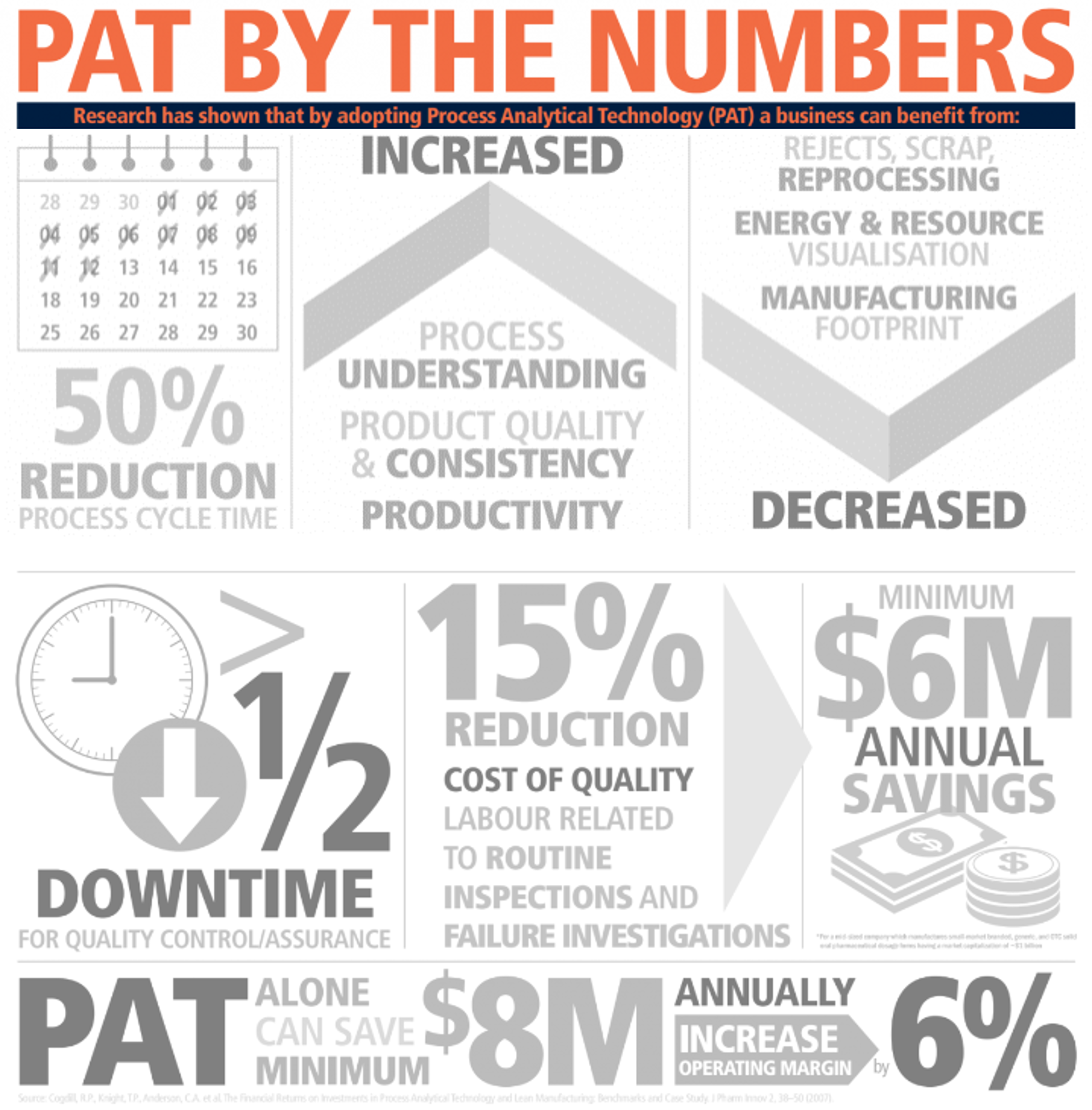

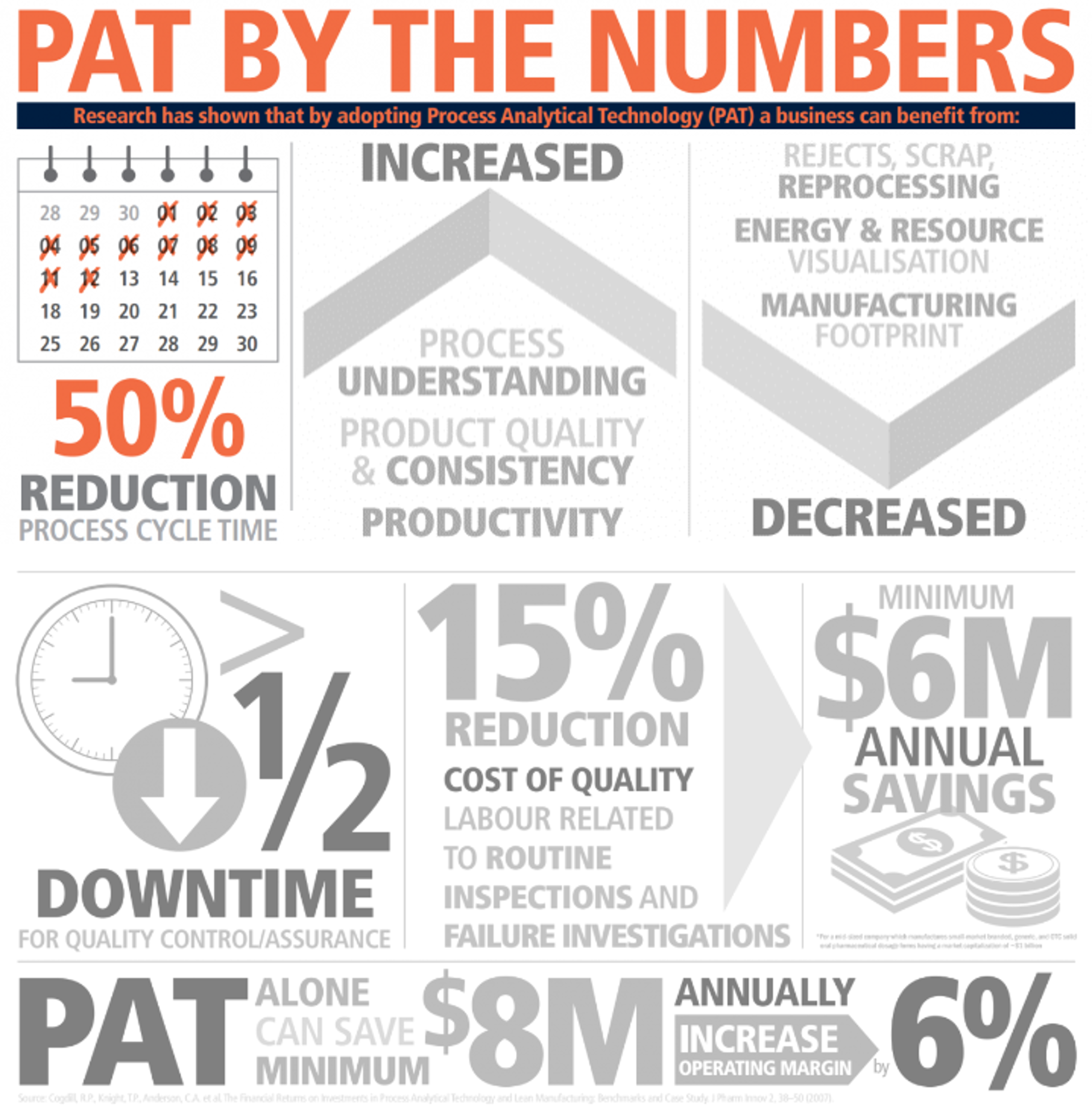

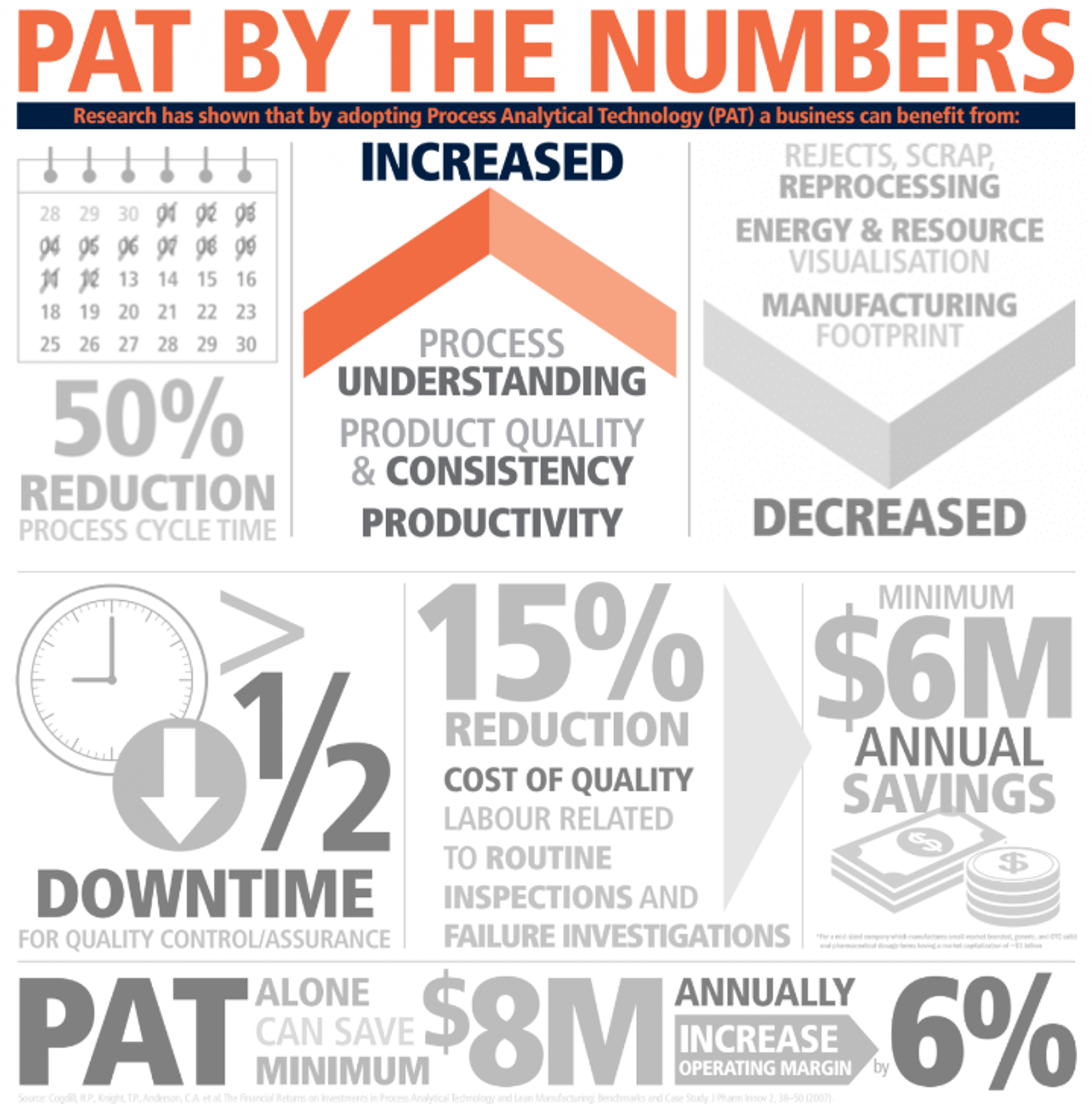

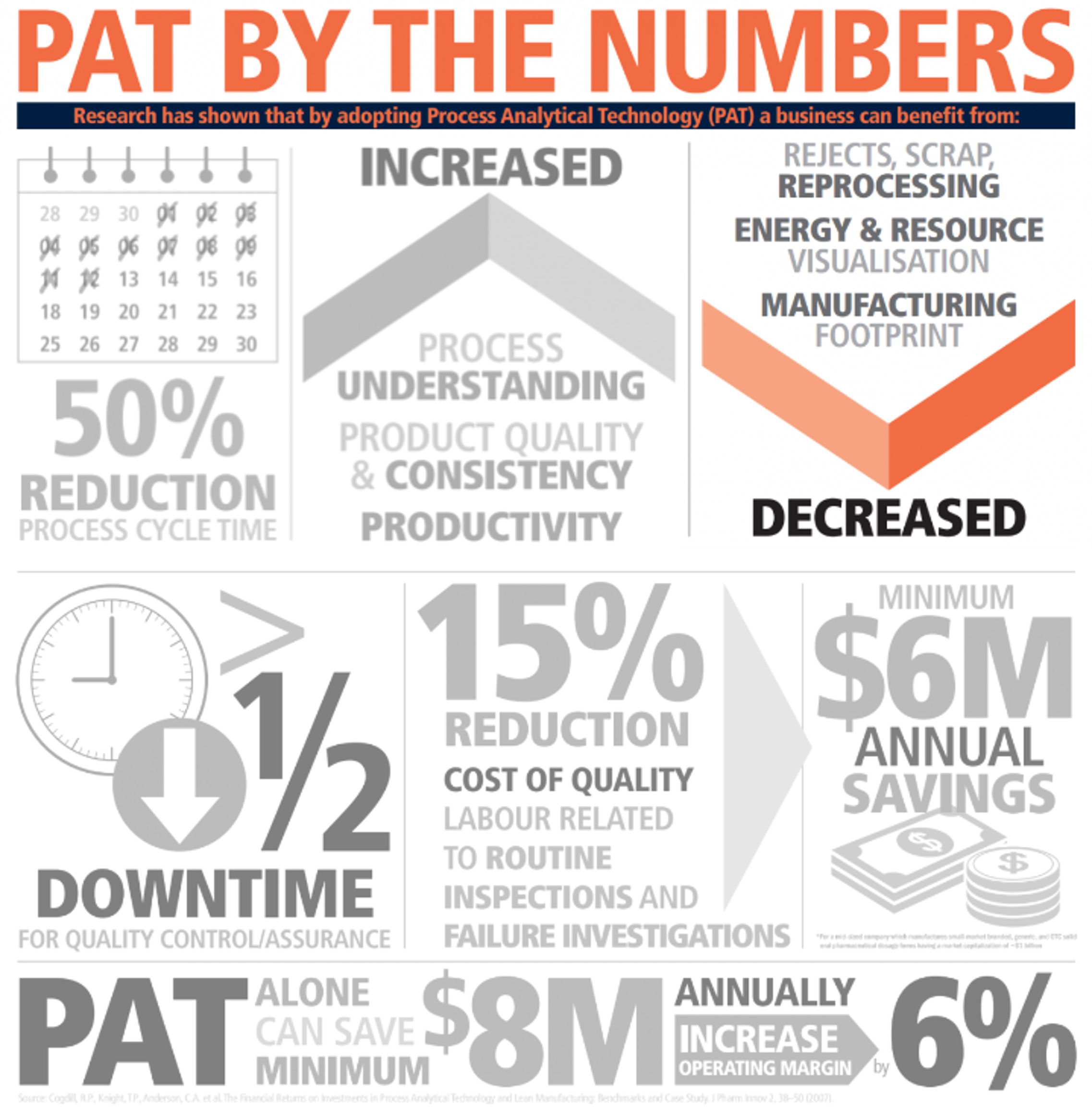

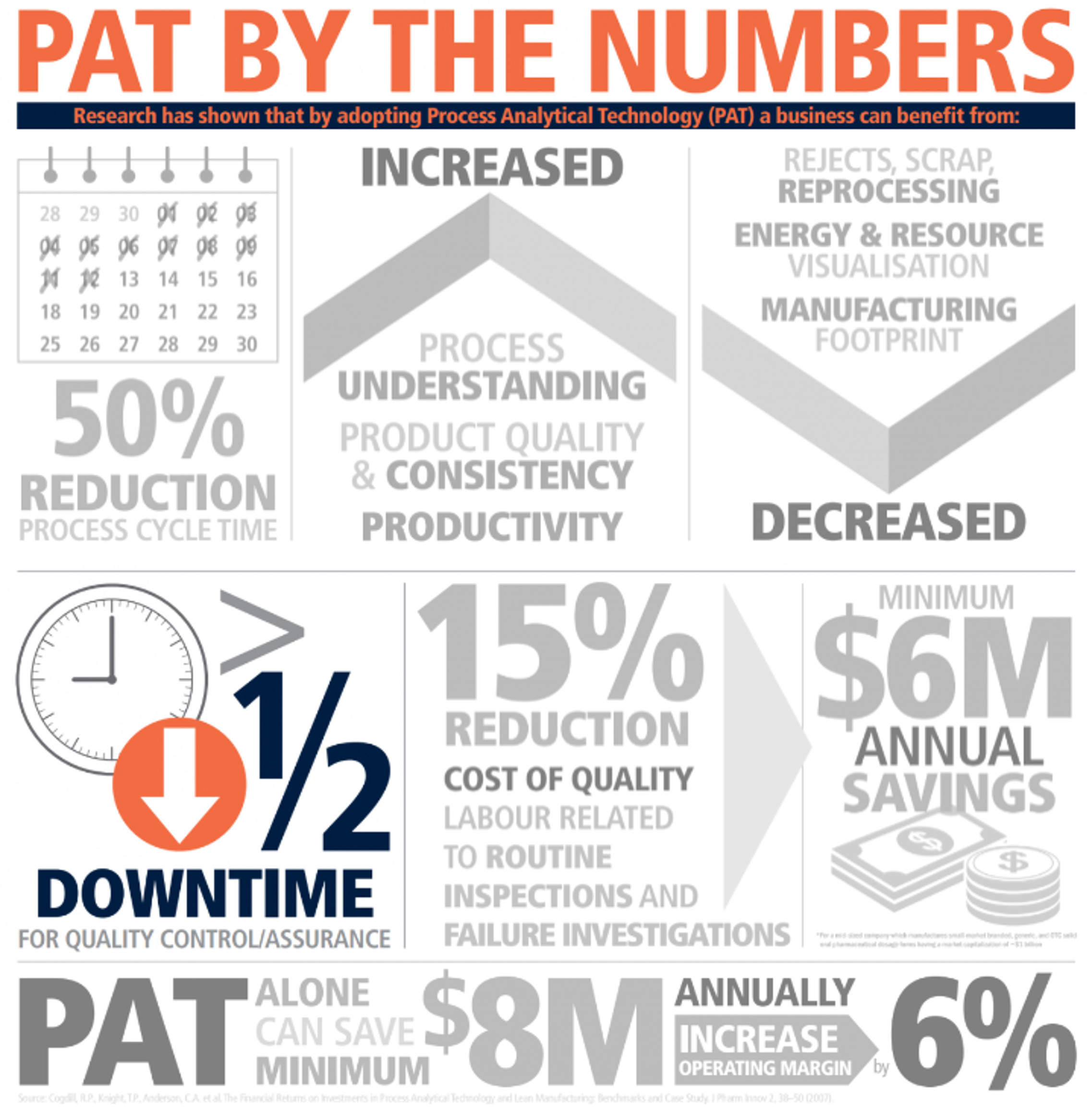

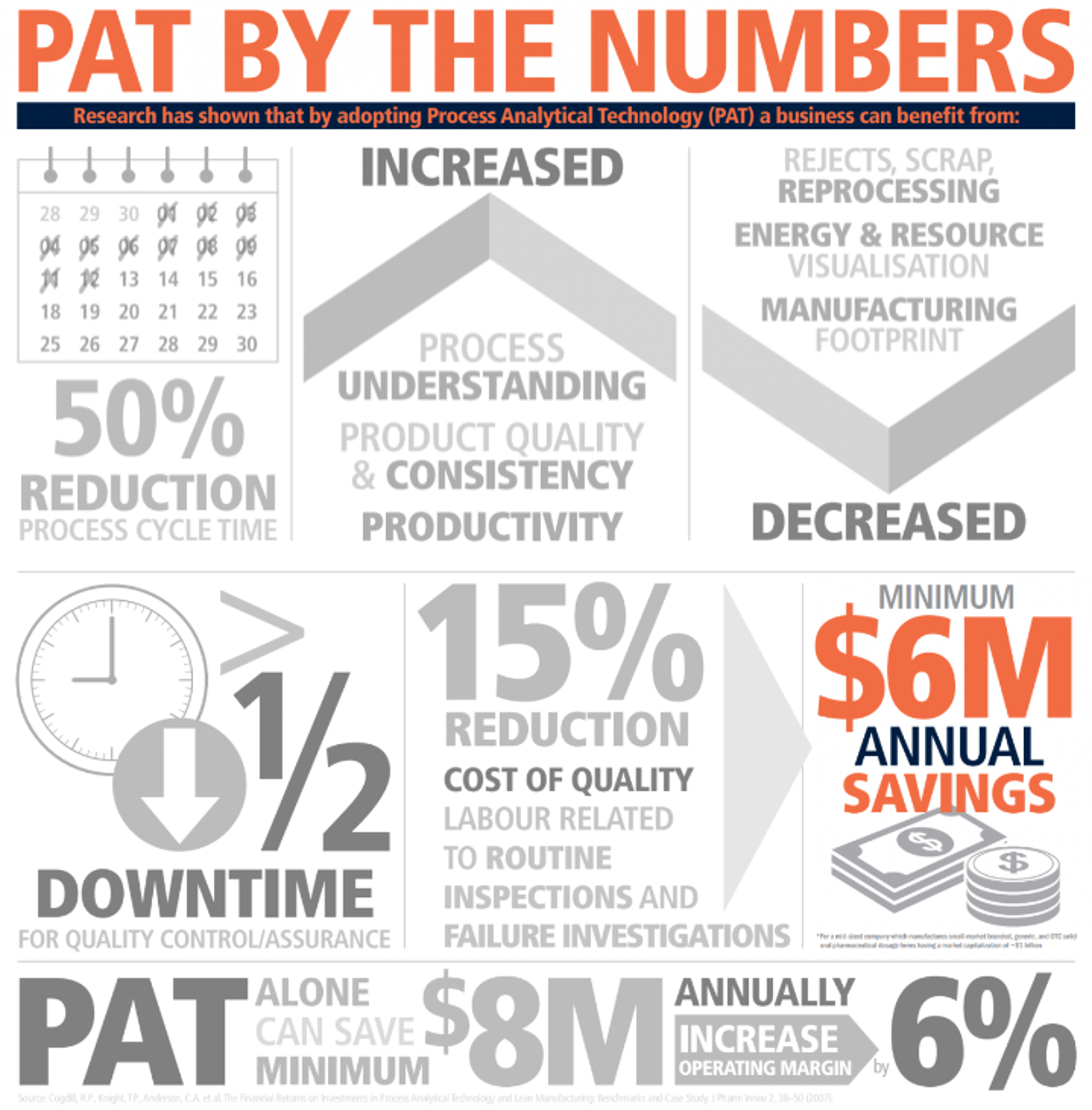

Better manufacturing operations with Process Analytical Technology (PAT)

Learn more about PAT Knowledge Manager synTQ. What the software does and why it is a must when deploying Process Analytical Technology (PAT).

Learn how to implement Process Analytical Technology (PAT). What skills does a business need? How to select the first PAT project? Where to start?

Process Analytical Technology (PAT) can help manufacturers get the most out of their production lines and deliver cost-effective, high quality products.

synTQ enables real-time process monitoring, control and improvement for life sciences manufacturers.

synTQ can be adapted to your aims and needs. It has been used to enable a range of innovative processes – including continuous manufacturing, real-time release and the ability to manufacture ‘just in time’. How does it work?

Top tips for a successful PAT Implementation:

1.Start small, think big

In our experience, the best way to prove the efficacy of PAT for your process is to begin with a smaller project. A good option is the better characterization of raw and in-process materials. Kicking off your PAT implementation with a successful first project will generate benefits, while giving the team experience and opening the door to larger, complex projects.

2.Be the champion

Ensuring that your PAT project is properly resourced with dedicated staff makes a successful implementation possible. A PAT Champion will be the driving force behind the project. They should be well versed in regulatory guidance and PAT technologies and communicate these with other relevant teams in the organization.

3.Orchestrate your instruments

A PAT system can be composed of a variety of hardware and software instrumentation: spectral instruments, MVA packages, control systems, and many more. Implementing a knowledge manager, such as synTQ, to direct them is essential to orchestrate the whole process.

4.Quality process, quality products – by design

The main purpose of PAT is to gain information about product quality and the workings of a process in real time to optimize quality, time and cost. Keeping Quality by Design values core to the process is key.

5.PAT is more than expensive analyzers

A PAT sensor doesn’t necessarily have to be the most well-known, expensive process instrument. Any sensor that can provide timely information about quality and its relationship to the critical process parameters (CPPs) should be considered to be a PAT instrument, regardless of its cost or complexity. PAT should be about knowledge management and implementation.

This text was adapted from our free eBook, QbD and PAT for Dummies. Download a copy for an in-depth guide to implementing QbD and PAT strategies, here: