Technical Features of synTQ

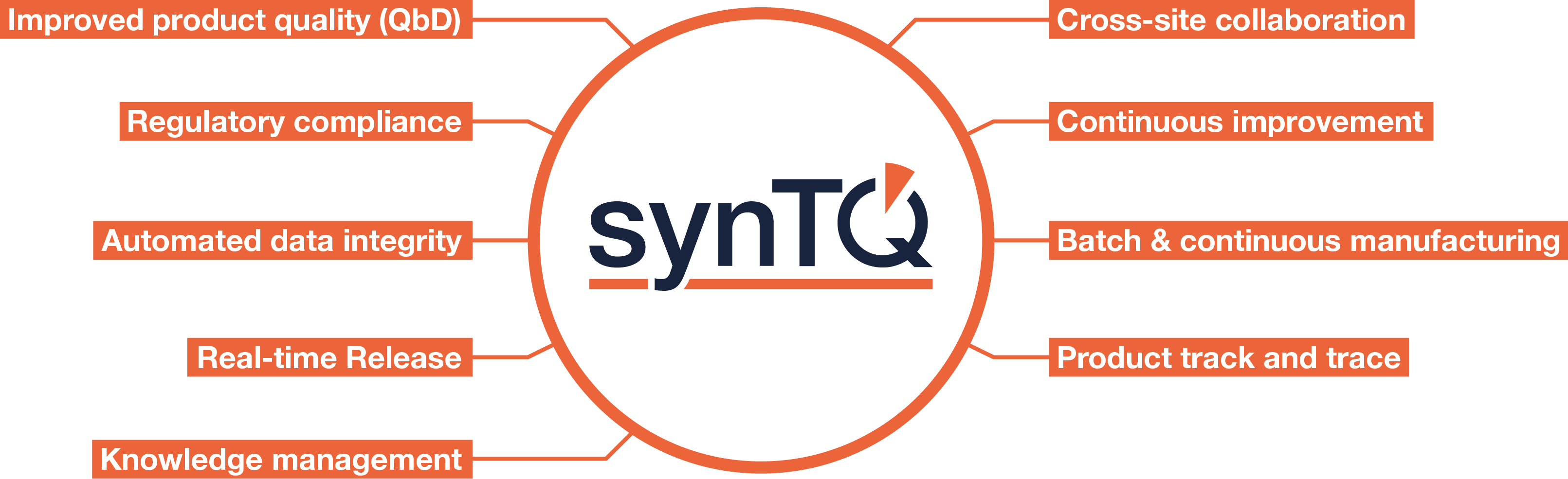

synTQ is the most mature product in the marketplace, offering a comprehensive set of easy-to-configure functions within a scalable product, that is used globally and backed by 24/7/365 support.

The synTQ website contains full details on the technical features of synTQ.

synTQ FM (Flexible Manufacturing)

synTQ FM is a fully flexible PAT knowledge manager that can be deployed on all systems and processes. synTQ drives quality-centric, real-time, closed-loop control into your process, optimising quality, time and cost.

synTQ Flexible Manufacturing (FM) meets the complete requirements demanded of a fully flexible PAT knowledge manager.

synTQ FM is the most comprehensive real-time version of synTQ, since it can interface to multiple instruments, multiple MVA packages, multiple control systems and can run multiple unit operations concurrently. It is a full client-server application that can run with no client (in headless/embedded mode) or with as many clients as you require.

Agnostic, fully flexible connectivity means that synTQ FM can connect to any device that has a communications interface and a known protocol. We have a large portfolio of adapters to third party hardware and software, which is continually expanding. If you require an adapter that we do not currently support, we may develop it for you free of charge.

synTQ is fully scalable. From a single small application running on an industrial, control-panel mounted PC through to a globally connected application running on virtually any Windows machine, virtual machine (VM) and the Cloud.

Depending on the application, multiple spectra and predictions are possible on any one synTQ node. A single synTQ node may in some applications connect to 100 or more spectral and univariate instruments.

synTQ EM (Enterprise Master)

synTQ EM centralises all of your PAT data into one place, simplifying data archiving. It also becomes the keystone in your PAT collaboration system, allowing you to share orchestrations and PAT models.

synTQ EM is the corporate/cloud-level application that connects to your synTQ nodes, which may be contained within one facility or distributed across the globe. If required, synTQ EM can be used to centralize your data (all measured, derived and configuration data) into one central point in your data center or the cloud, and then share this with authorized nodes in the global network.

For example, your models and methods that have been developed on one continent can be shared, when authorized, with your manufacturing facility on another continent. In this way, when your manufacturing sites are audited, all required configuration and metadata history is available to prove compliance.

synTQ EM does not connect to any instruments directly. As it oversees synTQ networks, it is not normally implemented until you have more than one system.

synTQ EM provides a view into every system in your synTQ infrastructure, and synTQ EM Clients can be distributed to any location in the world. Authorized personnel can view the operational status of any synTQ node in your infrastructure from any physical point that you require.

synTQ RS (Reporting Services)

synTQ RS facilitates the creation of printed and web-based PAT reports without adding load to your plant-level, real-time synTQ systems. The reports can be pre-configured or configured by authorised users, providing a flexible way of turning data into information.

synTQ RS is the reporting package used with synTQ to generate simple or complex reports. It is supplied with a number of pre-configured reports. Most reports must be created directly for you, as they are specific to your system and requirements. These can be built by your team, by Optimal, your local synTQ Partner or any other appropriately trained engineer.

Small reports may also be created using the mini batch reporter directly with synTQ FM, however if anything other than a single, simple report is required for your process then synTQ RS is the solution.

synTQ DFM (Dynamic Flow Modeller)

A practically applied material track and trace solution for mixed and plug flow continuous industrial processes.

synTQ DFM is a standalone package that may be run with or without synTQ. synTQ DFM provides a straightforward and practical method of tracking and tracing the materials moving through a continuous process to give you a regulatory compliant qualitative output.

When first embarking on a PAT-enabled continuous process, the need for track and trace may not be immediately apparent. However, once the system is running in production, the tracking of movement is critical for sampling, for rejection and for tracing starting lots to finished batches.

This type of product tracking is distinct from a traditional discrete tracking system. A continuous process often involves forward and back mixing to different levels throughout the process; process speed variation; product removal for sampling; the calculation of quantity; and the extraction of reject product from the line. For regulatory compliance and potential recall reasons, you must also know what starting raw material lots are contained in the finished batches. Track and trace is therefore a very complex but necessary function to apply to your continuous manufacturing process.

synTQ DFM includes an offline modelling package where the production line unit operations are configured ‘in silico’ together with the related movement algorithms. The system can then be run in real time, with sampling and rejection being controlled in a timely way together with data and reporting around the raw material lots in each of the finished batches. We have experience in deploying synTQ DFM in regulatory compliant systems.

Orchestration Functions

synTQ contains a range of internal functions that can perform multiple functions: from labor-saving basic operations to complex functions such as MSPC (Multivariate Statistical Process Control), synTQ AIC (Automated Intelligent Control), and Control Charts.

Our range of complex functions is ever increasing. We are always interested to learn from our customers of new functionality that we should consider. Many of these functions are bundled free with the synTQ framework, while others may be added as options. Get in touch with the team to learn more.

Third Party Adapters

Developed over the last 21 years, synTQ has grown to contain a broad and enviable range of third-party hardware and software adapters. These include:

- Spectral instruments

- MVA packages

- Control systems

- Historians

- Laboratory systems

- Remote I/O

There around 100 adapters to be used with synTQ at present. As we have a dedicated adapter development team, this range is continually expanding. In addition, even if your desired interface is not currently on our supported list, there is a good chance that we can develop it for you free of charge!